Company Profile

JacksonLea is a polishing consumable manufacturer with a history of more than 100 years. The company mainly produces various polishing materials such as solid and liquid polishing compounds, various polishing wheels, abrasive belts, Non-woven wheels, high-efficiency patented flap wheels, and Meter Buffs dedicated to robots; professional integration of traditional automatic polishing equipment, CNC polishing Equipment, robotic polishing equipment, and high-pressure airless spray gun systems used with automatic polishing equipment, as well as liquid polishing compound supply and transportation systems, such as pressure tanks and pressure pumps, etc...as an auxiliary equipment..

We are specializes in the production of polishing and grinding products with advanced equipment, assisting the polishing field in the integration of automated polishing systems. Products are widely used in electronics, bathroom, tableware, cookware, furniture, musical instruments (wind instruments, pianos, guitars), lockware, aluminum profiles, all kinds of hardware, aircraft parts, automobiles (dashboards, lacquer surface, aluminum wheels...).

Exhibits

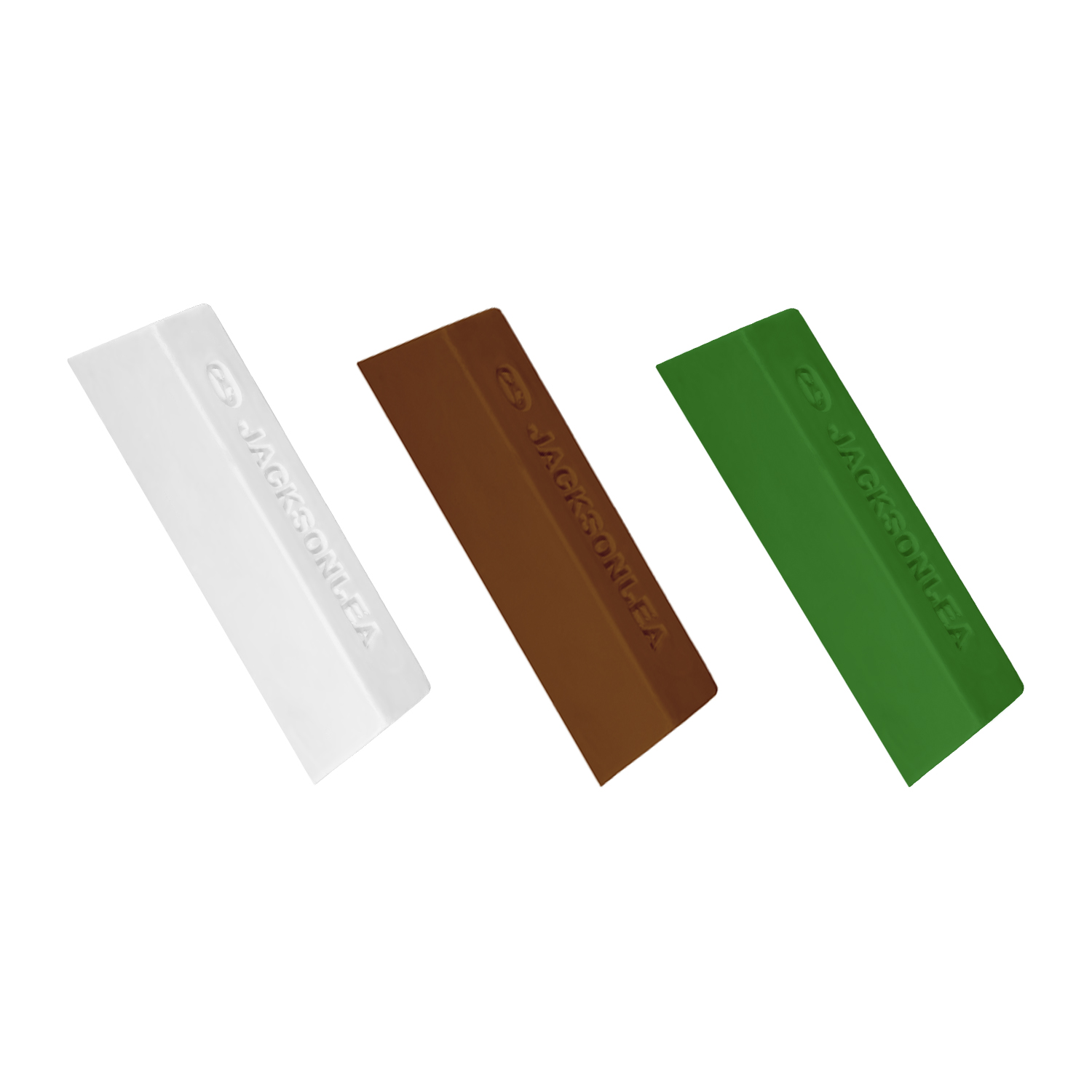

Bar Compounds

Polishing wax is a polishing material attached to the edge of the polishing wheel. On the basis of the high-speed rotation of polishing wheel, the polishing wax attached to the edge of the polishing wheel can enhance the polishing effect of the product surface.

Liquid Compounds

Polishing slurry is the liquid form of polishing wax. Attached to the edge of a high-speed rotating polishing wheel to enhance the polishing effect of the polishing wheel and also suitable for automatic polishing equipment.

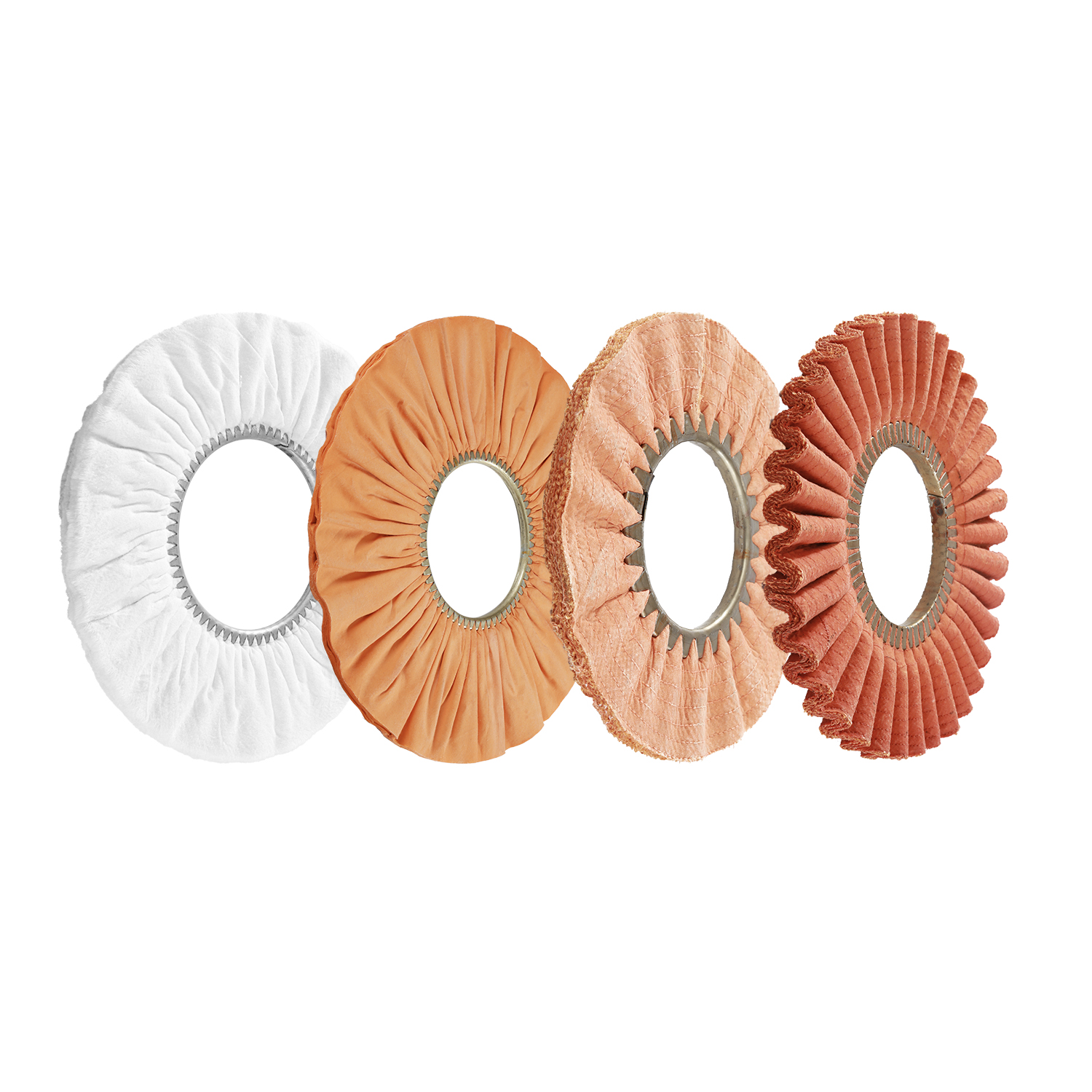

Polishing Buffs

Polishing buff, it is a pressing flat wheel, which is formed by several pressing polishing wheels, and the outer surface of each polishing wheel is evenly coated with a layer of polishing oil. There is no need to add oil separately during the polishing process. It has a simple structure and easy to use.

Spraying Gun System

The spraying gun system is applied to automatic polishing equipment, which can replace the traditional manual waxing process, reduce the time cost of waxing and wax replacement, improve the efficiency of the production line and avoid the risk of dry polishing.